Business Expansion: Best Time to Plant an Oak Tree – 1 of 2

December 2019 Article

By Tony Varela

Introduction:

It all started with a vision. Most people involved first heard about it nearly a decade ago. However, for Owner and President, Tim Varela, the vision of building his own manufacturing plant started many decades earlier. He knew that his vision of a successful business did not start and stop with the services it provided or the products it built, it included the building and land it was located in and on. He knew early on that he wanted to own and develop the land and facilities as well. So just where does one start when planning to purchase and develop land for a business?

Well, they say “the best time to plant an oak tree is thirty years ago. The second best time is today.” Many challenges go into developing your own building and it takes a great deal of planning and foresight to do it well.

- Does the company have a growth projection on the horizon to accommodate added costs of expansion?

- Is this the right time to put that amount of stress on the business?

- Just how much stress will it bring?

- How will the business manage changes and challenges associated with moving operations into a new facility?

This post is part of a two-part story of Meta Fab’s experience with our recent expansion and development of a new manufacturing facility in Hillsboro, Oregon. This project took a bit of luck, some skill and wisdom, and a great deal of vision.

Early Planning:

In large part, Meta Fab spent most years in operation as a commercial tenant, rather than a property owner. Over time, Meta Fab grew into every nook and cranny the building had to offer suggesting expansion into a larger building was long overdue.

Where and how?

Luck. The property owner behind the original site was looking to sell quickly, which opened a new opportunity for our company. The site came with a 10,000 sf building and plenty of room on three open acres for a future building. Meta Fab purchased this site in 2013.

Bubble Diagram

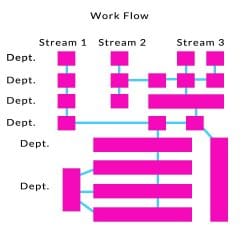

Work Flow Diagram

Vision and Wisdom. Later that year, Meta Fab met with OMEP: Oregon Manufacturing Extension Program to consult with their workflow and spacial layout professionals to develop the best workflow for our specific processes. Through this partnership, we were able to take a detailed look at our parts and processing centers. Through wisdom to know we needed support and a vision, Meta Fab took its first steps to arrange the precise space and departments we needed.

Skill. From years of experience and support from local resources, we were able to identify the amount of new space we would need for growth at a comfortable rate. Schematic drawings were done, an architect and a builder were identified; however, the timing didn’t feel right in a bull market so Meta Fab put the project on hold. Within a few years of strong growth, Meta Fab decided to move forward with its vision. We obtained secure lending, engaged a new builder and architect, and started the project. Here’s where the second part of that oak tree fable comes into play. No time like the present.

Finally, the decision was made to secure lending, engage a new builder and architect and start the project. Here’s where the second part of that oak tree fable comes into play. No time like the present.

The Kick-Off:

Perhaps a bit foolish, the decision to expand was halted as we insisted there would be a correction in the economy. Years passed and the economy kept surging, along with construction prices. We’ve always believed one can control their own destiny with planning and perseverance. The decision was eventually made to get started, regardless of what the economy was doing.

We had a few pre-application meetings with the local jurisdiction. This process was a bit like drinking from a fire-house. We decided to manage the project internally which had a lot of benefits, but if we’re searching for some good feedback, this might be one area. Having an experienced owner’s representative onboard may be beneficial in that they will know what questions to ask, where certain programs exist and other savings and incentives may be lurking. After the pre-app meeting, there were a few items like credits and incentives that were missed because we didn’t know exactly how to ask for them, or where to look. After some pain-staking meetings with the City, some common ground was found and the project found smooth sailing once again.

Another difficulty was managing the correspondence between the City planning dept and some of the parties on the design team. There were unknown delays where communications would drop off and have to be picked back up. Extra meetings were scheduled which meant lost time and more fees. A lot of this was due to the lack of experience within our internal team and managing design, construction, and planning teams and keeping all of them pushing forward to the same goal.

Breaking Ground:

Soon enough, permits were issued and we broke ground and hit the ground running.

Design, Building, Owner, and City posing for a picture during the groundbreaking.

At this point, we had an aggressive timeline to make up for the time lost during the planning & permitting process. Meetings were held bi-monthly with the building crew to make sure everything was staying on track. It was a straight forward construction plan for a pre-engineered metal building, but with any project, surprises will arise.

The design team was always available to answer any difficult RFI’s (Requests for Information) but the project eventually got to the point where most calls were made on location without the need for lengthy back-and-forth email conversations to get approval and clarification. The teams found a good rhythm.

For obvious reasons, proximity, the building team worked closest to the owner’s team and developed a strong process and flow of information. Expectations were set early and a heavy review of every change order was expected. When all was said and done, the change orders were managed and the project finished well below the expected scope creep that happens with any project.

Wrap Up:

There is a lot of moving pieces that go into building a new building. Even one that seems straight forward like a PEMB or Tilt-Up will have plenty of surprises and unforeseen challenges. Communication between the teams as often as possible really makes the project continue forward with as little hiccups as possible. Finding a great design and building team is also critical to the success of any project.

Thanks for reading. Look for our next installment on the expansion project coming out next month.