5 Key Proactive Steps Against Inflation for Manufacturers

By: Aimee Sukol, JD/MA/MS Ed.

Introduction: Inflation and Manufacturing

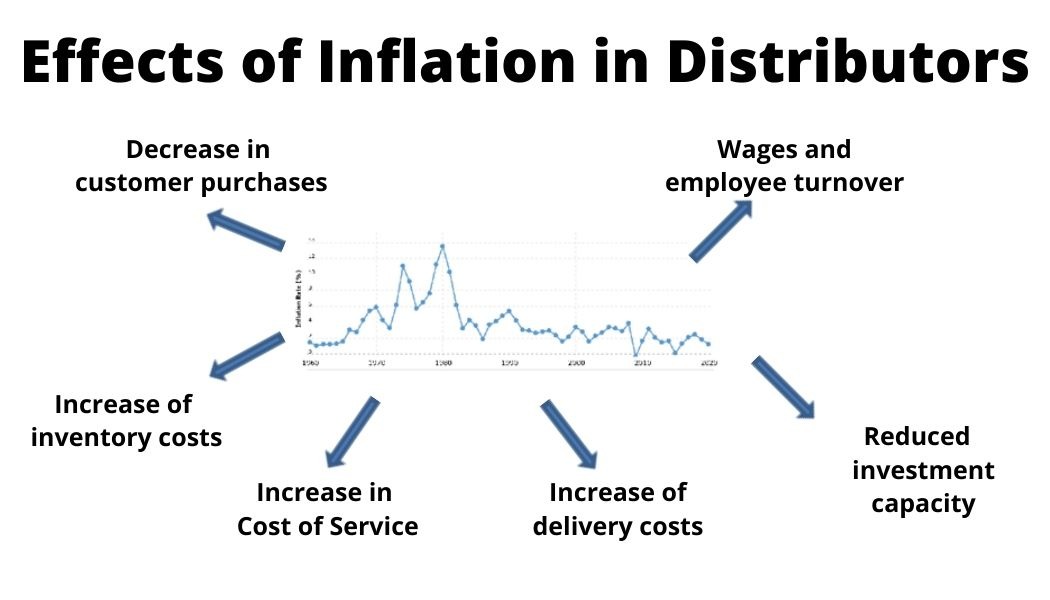

Inflation has impacted everyone globally without any clear predictions for relief in the near future. And while the pandemic significantly disrupted supply chains, consumer demand rose for goods and continued through the first half of 2022 despite signs of inflation. Service-related purchases, on the other hand, dipped and now with gasoline prices skyrocketing, inflation will continue to impact travel and product movement.

While consumer demand for goods has remained steady, inflation especially high gasoline prices will increasingly impact manufacturing and its ability to remain productive and profitable. Below are five protective actions against inflation.

1. Check in with customers and suppliers

Those closest to a company in the supply chain have the greatest impact. Are customers cutting orders? Do suppliers have enough inventory? Conducting a survey or setting appointments with customers and suppliers will help make informed decisions about purchasing and sales. Sales reps should be informed of issues leads face prior to speaking with them so they can touch on what your company can do for them in light of global and economic conditions.

2. Review your relationship with other countries

Where are your customers, suppliers and their supply chain located? Companies should know how and where their supply chain is most vulnerable and secure substitutes if necessary. Customers and suppliers could be experiencing a host of issues depending on their location so having a back up plan for geographic realities helps to control internal processes and pace of production.

3. Get ahead of price increases

Companies do not want to be the last to realize that costs of production have increased for everyone in the supply chain. To minimize the impact of increased costs, a company should have a strategy for its own price increases and messaging to customers when that occurs. Messaging is particularly important to avoid damaging customer relationships so a thoughtful plan should be laid out for type(s) of service/product, select or all customers, and rate of price increase.

4. Continue to invest in your business

Short term decision-making is important as global events and costs change rapidly; however, a company’s big picture remains important. Continued investment prepares a company for post-inflation stabilization and secures a competitive advantage. This means continue plans for technological integrations and capital investments that have anticipated bottom line advantages.

5. Avoid Employee Layoffs/Exodus

5. Avoid Employee Layoffs/Exodus

Perhaps the most important protective action a company can take is to avoid turnover and invest in workplace satisfaction. Faced with inflation, it is not uncommon for companies to cut their labor costs, but this is not the time for layoffs or to encourage workers to seek employment elsewhere especially as manufacturers have struggled to build and retain a qualified workforce. Workers’ costs are also increasing and they may be looking for more lucrative opportunities. Consumer demand has remained steady and when prices stabilize, work orders will continue to require high capacity production. A competitive company will have a steady crew to resume regular production at previous or new volumes.

Conclusion

In short, manufacturers are highly susceptible to inflation, but proactive decisions in pricing, evaluation, investment, customer service and workplace satisfaction can offer stability to ride out heavy storms.

For more information about how to protect your operation from inflation, check out the Oregon Manufacturing Extension Partnership (OMEP) and for information about Meta Fab’s full service sheet metal fabrication services, contact our sales team at sales@metafab.com.

References: