Bringing On A New Sheet Metal Fabricator

January 2020

By Tony Varela

Introduction:

If you are looking to develop and manufacture a new product, it is critical that you find the right suppliers and ensure the product or service they supply is what you need to make the project a success.

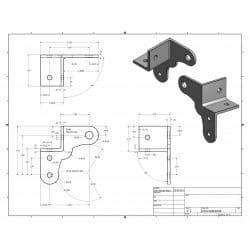

If it is a physical product with electronics or sensitive internal components, chances are you will need some enclosure to house your electronics. Sheet metal fabrication is an extremely common and cost-effective way to make a custom enclosure that will both house your product and set you apart from the competition. To help you bring these custom products to life, get in touch with our experienced engineers and fabricators and we can help you land on the perfect design and help you get to market in a fast and cost-effective way. At Meta Fab, Inc., we are able to fabricate metal products with precision and professionalism.

Meet Meta Fab:

Our skilled team of fabricators comes with years of experience and a proven process. We have worked on some incredible projects that range from the medical industry, aerospace, consumer electronics, and security devices among many others, which require the ultimate precision and expertise.

Having worked on a wide range of products and industries, our team has gathered a significant and diverse knowledge base on how to arrive at the desired outcomes of any precision sheet metal fabrication project. In addition to the vast knowledge our fabricators bring to the project, we also employ the latest technologies and metal processing equipment on the market. These advanced machining and CNC processing centers allow us to make radical customizations to meet your project’s needs and exact requirements.

Having worked on a wide range of products and industries, our team has gathered a significant and diverse knowledge base on how to arrive at the desired outcomes of any precision sheet metal fabrication project. In addition to the vast knowledge our fabricators bring to the project, we also employ the latest technologies and metal processing equipment on the market. These advanced machining and CNC processing centers allow us to make radical customizations to meet your project’s needs and exact requirements.

Many fabricators out there offer different aspects to the precision sheet metal fabrication process, however, few of them bring as many of the processes in-house as Meta Fab, Inc. has done. By doing this, Meta Fab is able to control quality throughout and decrease the lead-time of projects that makes them one of the most competitive precision sheet metal fabricators in the Portland metro area and the greater Pacific Northwest.

Choose Your Materials:

Meta Fab, Inc. works with many metal variations but the most common are Stainless Steel, Cold-Rolled Steel, Galvanized Steel, 5052 Aluminum, and some Copper.

Steel and many variants it comes in is a good and cost-effective material, however, corrosive materials need to have some sort of finish process to keep it from rusting. Powder coating is a process in which a plastic powder is sprayed on to metal parts and baked at a high enough temperature to melt the plastic into a tough, durable; coating that protects the material from corrosion. Two materials that are highly corrosion resistant are stainless steel and aluminum.

Our engineers have decades of experience working in metal and can help you in selecting the best material and finish needed for your project. Meta Fab, Inc. has built a strong supply chain of metal suppliers and other finishing processes like plating and anodizing. Meta Fab, Inc. truly is your one-stop-shop for all precision sheet metal and machining fabrication.

Send us your CAD, models, or shop drawings and receive a quote today!